SCHUTZEN Chemical Group

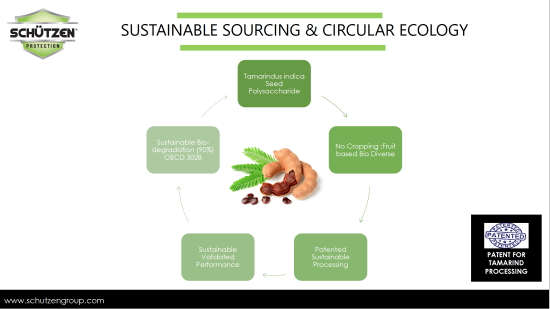

The India-based start-up SCHUTZEN Chemical group has developed new technologies for processing polymer from tamarind seed and gaining desired properties that enables it´s use in textile printing and dyeing processes. This makes textiles products more sustainable, as the innovation of SCHUTZEN Chemical Group can replace some hazardous chemicals used in textile treatments. Beyond that, their sustainable products can be used as a natural alternative in skin and hair care products, as well as in the paint and coating industry. For these reasons, SCHUTZEN Chemical Group has been chosen as ISC3 Start-up of the month for June 2021.

Year of Foundation:

November 2015

Addresses the following SDGs:

SDG 9 (industry, innovation, infrastructure), SDG 12 (responsible production and consumption), SDG 13 (climate action), SDG 14 (life below water), SDG15 (life on land)