Establishing new standards to achieve the Sustainable Development Goals is a huge challenge for industry and business, as the companies mostly implement individual measures which tend to be rather time-consuming and cost-intensive due to large number of safety and compliance regulations. Open innovation approaches aim to simplify these processes and bring entrepreneurs together for a common goal. Such an example is the sustainable eco-friendly COKOON technology developed by Continental and Kordsa. COKOON`s free licensing pool helps secure the supply base and enables the collection and sharing of industry research and development whilst also including free of charge sampling and thus the technology works as an accelerator and catalyst towards a more sustainable future.

COKOON Dip Technology

New technology and business model towards sustainability in the tire industry

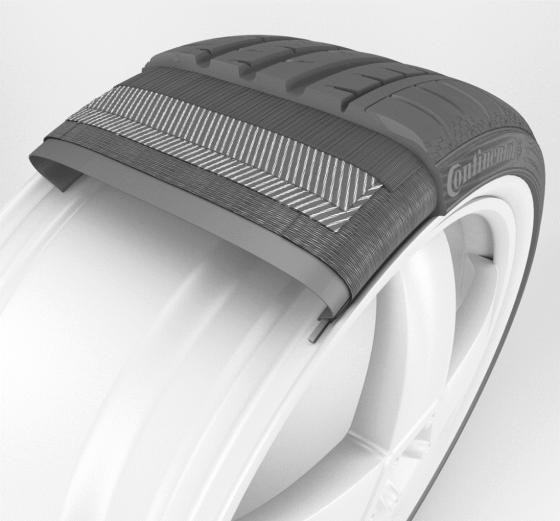

COKOON was developed to promote a sustainable adhesion technology that serves to interconnect the textile and rubber layers of tires. During tire manufacturing a rubber matrix needs to be connected to a textile layer made of e.g. polyester or nylon. High quality tires must meet many requirements: performance, endurance, safety and sustainability. Therefore, textile plies need an excellent bonding to the rubber. This basically requires “some sort of a glue that is able to interconnect textile fiber and rubber matrix”, explains Mr. Kramer (Continental). For about a century now, the most commonly used technology for this purpose has been Resorcinol Formaldehyd Latex (RFL) dipping. Other than in the tire manufacturing industry, RFL dipping is also widely used in the production of mechanical rubber goods, such as conveyor belts, hoses, or power transmission belts.

Continental and Kordsa have production facilities and units that apply this type of coating on textile fibers, but which its new technology both partners have started replacing the RFL adhesive technology. And is there a good reason to replace RFL dipping? Formaldehyde is a known carcinogen above certain threshold values and resorcinol is also being tested on possible endocrinic disruptive effects. Both chemicals are used early in the production chain. End users are not freely exposed to the chemicals, as they have been chemically modified by the vulcanization process. “Although we do fulfill all legally valid threshold requirements, we believe it to be our responsibility to eliminate hazardous substances wherever possible and to seek for non-hazardous replacements. Therefore, we constantly analyze and review all raw materials used producing our tires. By 2050 Continental wants to use 100 percent sustainably produced materials in its tire products. A project like COKOON is one important step on this way”, Mr. Kamer states. And it was this strong resolution that led Continental and Kordsa to develop COKOON Dip Technology. Up to now, about 250,000 COKOON dipped tires have already been produced, which is a small fraction compared to a total production of 150 million tires per year. But, considering the many time-consuming and cost-intensive process steps that a completely new technology needs to undergo until it is approved and tested, this is already a significant fraction. And there is more news to it.Continental’s and Kordsa’s new technology is complemented by the introduction of a new business model. “Innovation is key for differentiation. Generally, this idea applies to individual products that can simply be marketed. But producing and innovating components leads to a huge impact on other systems, it also extents to areas such as tire metrics. Each and every step needs to be carefully assessed,” Mr. Ilgün (Kordsa) explains. Most companies focus on inhouse-based sustainable R&D projects that generate only limited returns for their owners. Kordsa’s and Continental’s free of charge COKOON licensing model makes their new dipping technology accessible to all interested parties such as tire and textile suppliers. Any registered platform member that has signed the platform license agreement is granted free access to their COKOON Dip Technology and gets the option to help contribute to its improvement.

In return, it is expected that patents deriving from further enhancement of this shared technology shall be made available to all other platform partners free of charge. Developments and IP which are not touching this technology does not need to be put in this pool.

The COKOON licensing pool is coordinated by a third party, an independent IP consulting firm called AdvInno. “It requires a different way of thinking”, says Mr. Kramer (Continental), “as there are numerous companies developing alternative technologies and patenting them, trying to protect their own solutions. Such a competitive approach brings more challenges to the market, as tire manufacturers will have to compare and deal with many different adhesion systems that all need to be independently approved and tested first. However, this way of thinking does not entail any benefits for tire performance, will cost time and resources and will most likely lead to increased costs for tire end customers.” COKOON can be applied on standard production equipment which means avoiding extra investments for changes in the production processes. Like this, COKOON`s free licensing pool helps secure the supply base and enables the collection and sharing of industry research and development whilst also including free of charge sampling. Also, the technology works as an accelerator and catalyst towards a more sustainable future, since individual measures normally taken by businesses tend to be rather time-consuming and thus entail delayed effects due to a large number of compliance and safety hurdles.

Since the first announcement of COKOON as an open innovation technology in March 2019, it has attracted a lot of attention within the industry. Up to now, more than 70 companies have expressed interest in this new eco-friendly dipping technology, and it continues to be trending. According to Continental and Kordsa, this signifies that the ice is broken regarding acceptance of the new approach. With their unique COKOON Dip technology and its free licensing pool as a business model, the two corporates aim at providing a basis for joint tire industry standards towards a more sustainable development. But establishing new industry standards will only become reality if many more companies and start-ups join in and partner up and help finding solutions together. In this way, COKOON’s open innovation approach pursues a common goal with the ISC3 Global Start-up Service - both platforms seek to accelerate the process of driving sustainable innovations to market maturity.

Website:

Contact: